Precision HVAC for Wind Turbine Manufacturing

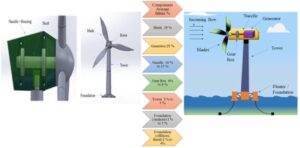

Manufacturing wind turbines is one of the most challenging industrial applications for HVAC design. With massive hangars, high ceilings, constant crane and vehicle movement, and critical environmental requirements for blade curing and finishing, precise control of temperature, humidity, and air quality is essential.

WCSIPL has successfully delivered HVAC solutions for large-scale wind turbine projects in India, combining technical expertise, practical experience, and a deep understanding of manufacturing challenges to provide reliable, continuous, and defect-free production environments.

Challenges in Wind Turbine Manufacturing HVAC

Large-scale hangars & overhead cranes

- Blade manufacturing requires hangars over 20,000 sq. m. with heights of 21 meters.

- Overhead cranes and regular material movement obstruct air distribution, complicating airflow design.

- High ceilings mean cooled air must be delivered efficiently to the occupied space without creating turbulence or dust circulation.

Humidity control in coastal zones

- Many plants are located near ports with high ambient humidity.

- Maintaining proper humidity is crucial for FRP blades to ensure curing quality.

- Root joint areas require positive pressure to prevent outside moisture from affecting the blade’s base structure.

Dust management

- Finishing sheds generate heavy dust during grinding, painting, and surface treatment.

- Dust must settle quickly; return air ducts are positioned low on walls to avoid floating contaminants.

- Two-stage filtration systems ensure a clean, safe environment while protecting worker health.

Process-specific environmental requirements

- Root Joint Areas: Continuous 24/7 operation with humidity control and positive pressure to maintain structural integrity of blades.

- Moulding Areas: Chemical curing requires carefully controlled air velocity, avoiding condensation and ensuring proper bonding of coatings.

- Finishing Areas: Dust-heavy environments require specialized air terminal devices and air diffusion design to prevent re-entrainment of particles.

Temperature control for curing and coating

- Precise temperature regulation is essential for chemical processes during molding and finishing.

- Air speed and temperature must ensure even curing without affecting coating quality.

Our Approach

- Customized HVAC design for each process and hangar zone, ensuring consistent temperature, humidity, and airflow.

- Positive and neutral pressure zones to prevent contamination and moisture ingress.

- Specialized air terminal devices for jet and diffusion applications to control velocity and air distribution.

- Dust management solutions with low-mounted return ducts and multi-stage filtration systems.

- Continuous operation systems capable of handling shutter openings, crane movement, and high traffic without disrupting environmental parameters.

WCSIPL Expertise

- Handling facilities over 20,000 sq. m. with 21m ceilings.

- Expertise in high-humidity coastal locations near ports.

- Tailored solutions for root joint, molding, and finishing areas.

- Continuous monitoring and maintenance support to ensure uninterrupted production.

HVAC Capacity

Project Budget

Project Reference

Client: Nordex India Pvt Ltd, Thiruvallur, Chennai

Successfully delivered a fully customized HVAC system addressing all process, environmental, and operational challenges.

- – Educational Facility

Need more help?

We’re here to answer any questions you may have.

Why is HVAC so critical in wind turbine blade manufacturing?

How does WCSIPL handle high-humidity coastal environments?

Systems are designed with positive-pressure zones, humidity control, and continuous operation to prevent moisture ingress and maintain consistent conditions.