Efficient Industrial & Food Drying Solutions

A wide range of drying methods

There are a lot of different drying methods. The most common are sun drying, hot air drying, contact drying, infrared drying, freeze-drying, fluidized bed drying, and dielectric drying.

Depending on the nature of the products to be treated, either foodstuff or industrial material, these methods prove to be more or less adapted.

Hot air drying

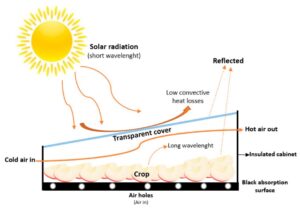

Sun drying

Contact drying

Infrared drying

Infrared drying evaporate water or solvent at high temperature. It can also be coupled with hot air and is used when the drying effect must be concentrated on the surface of the treated product to also obtain a roasting effect.

This solution is far from ideal for products that should not be exposed to high temperatures.

Freeze-drying

Freeze-drying process is based on the water sublimation effect in a low temperature and low pressure environment. It is often recommended for the drying of temperature sensitive food products, as it preserve most of the organolpetic properties.

On the other hand, freeze-drying is relatively slow and expensive technology, and is mainly a batch process as it works at low pressure.

Fluidized bed drying

This technology consists of mixing air and solid particles so that the whole behaves like a fluid. It is mainly used to dry seeds or grainy materials. This drying method is most of the time really quick.

On the other hand, the treated product is subjected to a high temperature which can denature it.

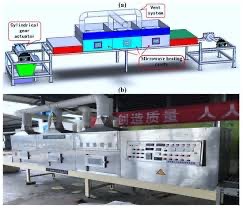

Dielectric drying

Last but not least, the drying by microwave and radio frequency is based on the dielectric drying technology. By heating the entire volume of the product simultaneously, it is particularly recommended in applications where homogeneous and gentle drying is required.

This solution is the most adapted for drying heat-sensitive products in the food, industrial and medical field, to preserve all of their properties.

- – Drying Solutions