Powder Handling Excellence HVAC Solutions

Specialized Climate Control for Spices, Dairy Powders & Additives

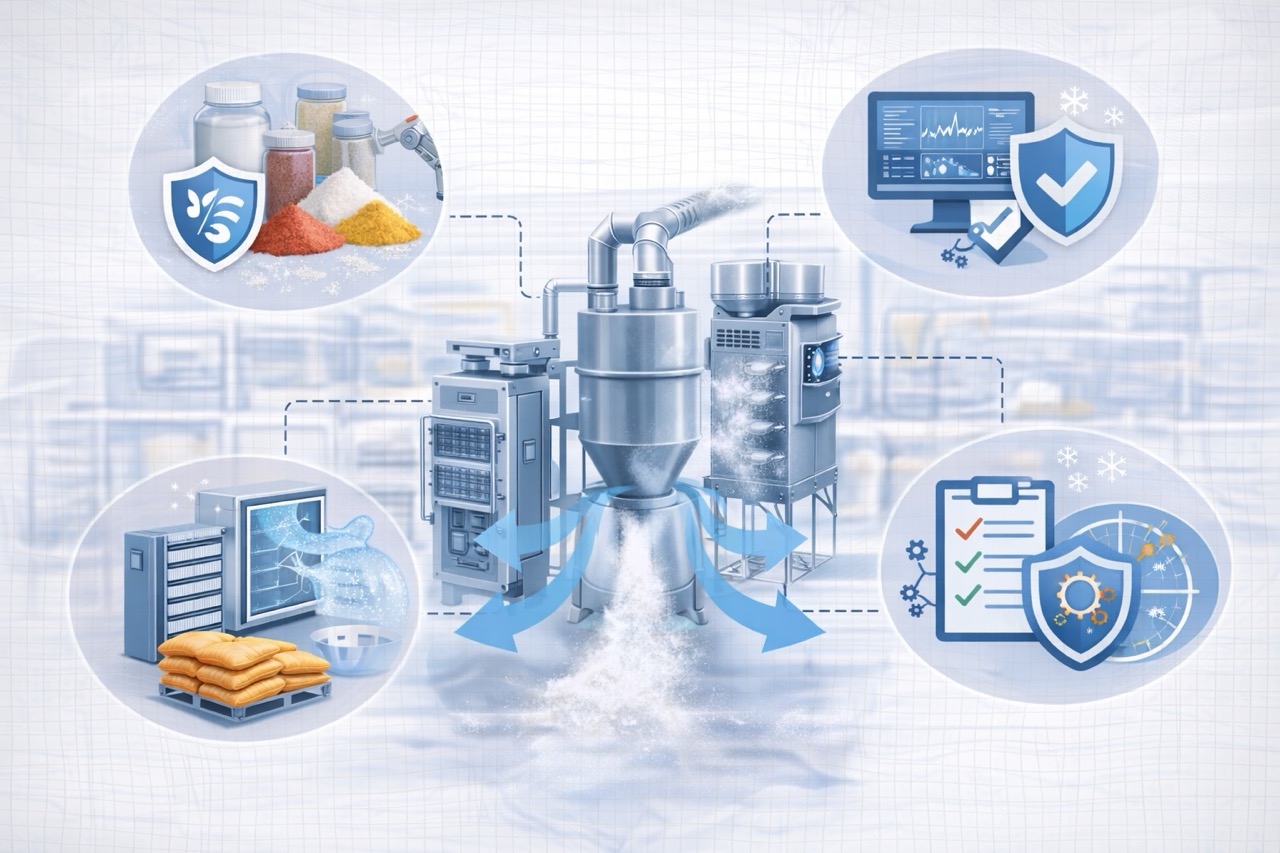

Powder processing in the food industry presents unique challenges due to the fine particulate nature of the materials. Spices, dairy powders, and additives are highly sensitive to environmental conditions, and even minor contamination can compromise product purity and safety. WCSIPL provides customized HVAC solutions designed to maintain a clean, controlled environment for efficient powder handling, ensuring compliance with food safety standards and optimal product quality.

Why Specialized HVAC is Critical for Powder Handling

Contamination Prevention

Fine powders are highly susceptible to airborne contamination.

Product Purity

Maintaining controlled environments ensures spices, dairy powders, and additives meet the highest quality standards.

Regulatory Compliance

Hygienic processing areas are essential for meeting stringent food safety regulations.

Worker Safety

Advanced dust control systems reduce airborne particulate exposure, improving workplace conditions.

Key Features of WCSIPL Powder

Handling HVAC Solutions

Dust Control

- Advanced filtration systems capture airborne particles at the source, preventing contamination and product loss.

- Reduces risk of cross-contamination between different production batches.

Positive Pressure Systems

- Controlled pressure differentials ensure that external contaminants are prevented from entering processing areas.

- Maintains hygienic conditions essential for high-purity powder production.

Multi-Stage Air Filtration

- HEPA and other advanced filtration systems remove fine particulates from the air.

- Ensures compliance with food safety and hygiene regulations.

Environmental Monitoring & Control

- Precise control of temperature, humidity, and airflow to maintain powder integrity and prevent caking or clumping.

Key Benefits

- Ensures product purity and safety for spices, dairy powders, and additives.

- Prevents airborne contamination, maintaining hygienic processing conditions.

- Reduces product loss and ensures consistent quality.

- Improves worker safety and operational efficiency.

- Fully compliant with food safety regulations.

Powder Handling (Spices, Dairy Powders, Additives) Applications

- Maintain low-humidity zones to prevent clumping and product degradation.

- Use negative-pressure extraction for grinding, blending, and sieving operations.

- Apply high-efficiency particle filtration such as cartridge or bag filters.

- Adopt stainless steel ducting for hygiene and easy cleaning.

- Create dust-free processing rooms to maintain product quality.

Why Choose WCSIPL?

- Expertise in handling fine particulate food products.

- Custom solutions tailored to specific powder types and processing requirements.

- Advanced filtration and exhaust systems for hygienic and safe working conditions

- Advanced technology ensures reliable performance, hygiene, and regulatory compliance.

- Focus on maintaining product integrity and safety while optimizing operational efficiency.

Weather Controlling Solutions India Pvt. Ltd. (WCSIPL) delivers Powder Handling Excellence HVAC Solutions engineered for food, nutraceutical, dairy, spice, and dry ingredient processing facilities where airborne particulate control, hygiene, and process stability are critical across Pune, Maharashtra, Gujarat, Chennai, Delhi NCR, Telangana, Hyderabad, Andhra Pradesh, and pan-India. With over 17 years of turnkey engineering expertise, we design and execute industrial HVAC systems that effectively manage dust containment, controlled airflow patterns, temperature and humidity regulation, and differential pressure zoning across powder handling, blending, sieving, filling, and packaging areas. Our solutions are focused on minimizing cross-contamination, preventing moisture-induced agglomeration, improving operator safety, and maintaining product integrity through precisely engineered ventilation, filtration, and clean air distribution strategies, seamlessly integrated with utility piping, process exhaust, and fire-fighting systems. WCSIPL’s design-build approach aligns HVAC performance with process requirements and material behavior rather than generic comfort standards, enabling powder processing plants to achieve audit compliance, consistent product quality, energy-efficient operations, and scalable infrastructure that supports long-term manufacturing excellence.

- – Powder Handling HVAC Solutions

Our specialists are ready to deliver customized, efficient, and reliable cooling solutions for your industrial needs.