Two-Stage Evaporative Cooling for Maximum Efficiency

Advanced indirect-direct systems for precise temperature and humidity control.

Advanced Ventilation for Safer, Cleaner, and Efficient Snack Production

How It Works

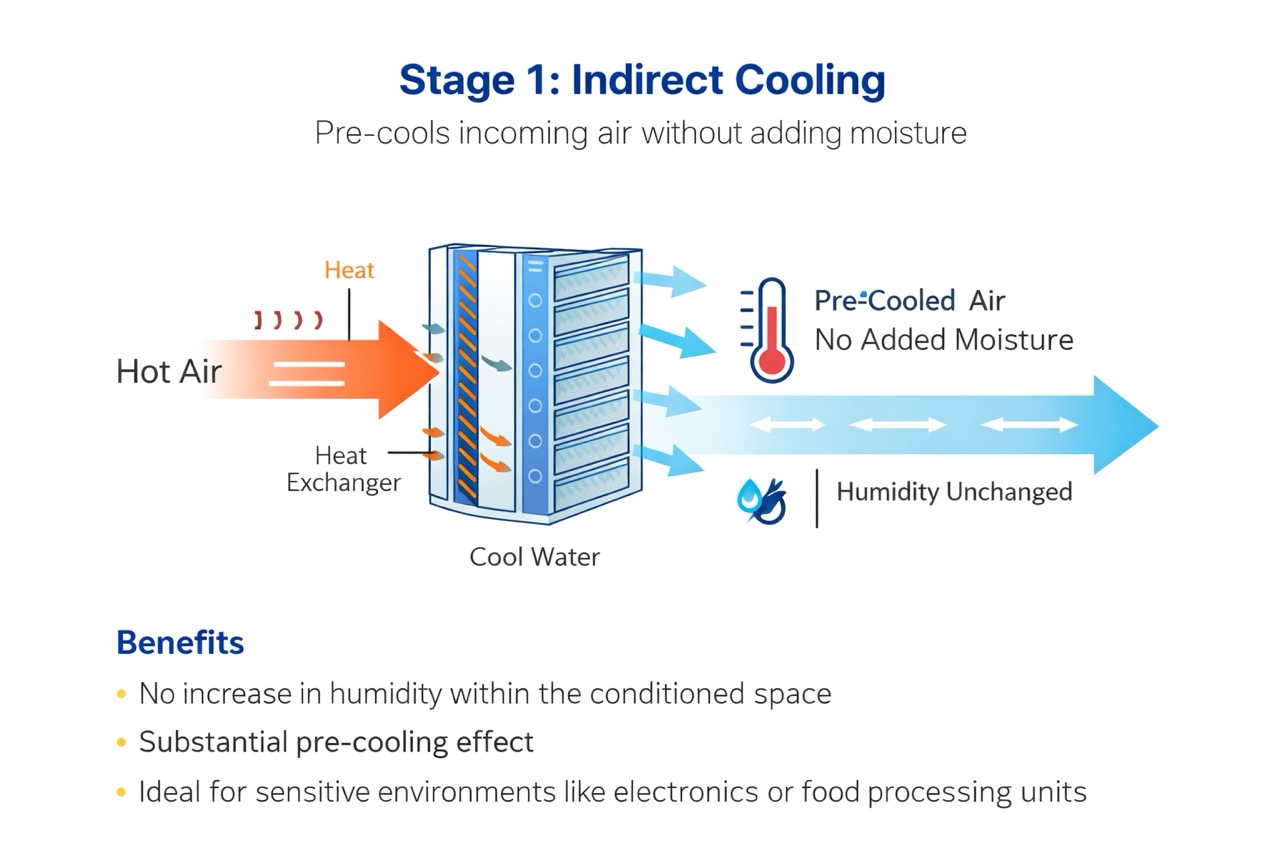

Stage 1: Indirect Cooling

In the first stage, heat exchangers pre-cool incoming air without adding any moisture. Thermal energy is transferred efficiently, reducing the air temperature while maintaining its original humidity level.

- No increase in humidity within the conditioned space

- Substantial pre-cooling effect

- Ideal for sensitive environments like electronics or food processing units

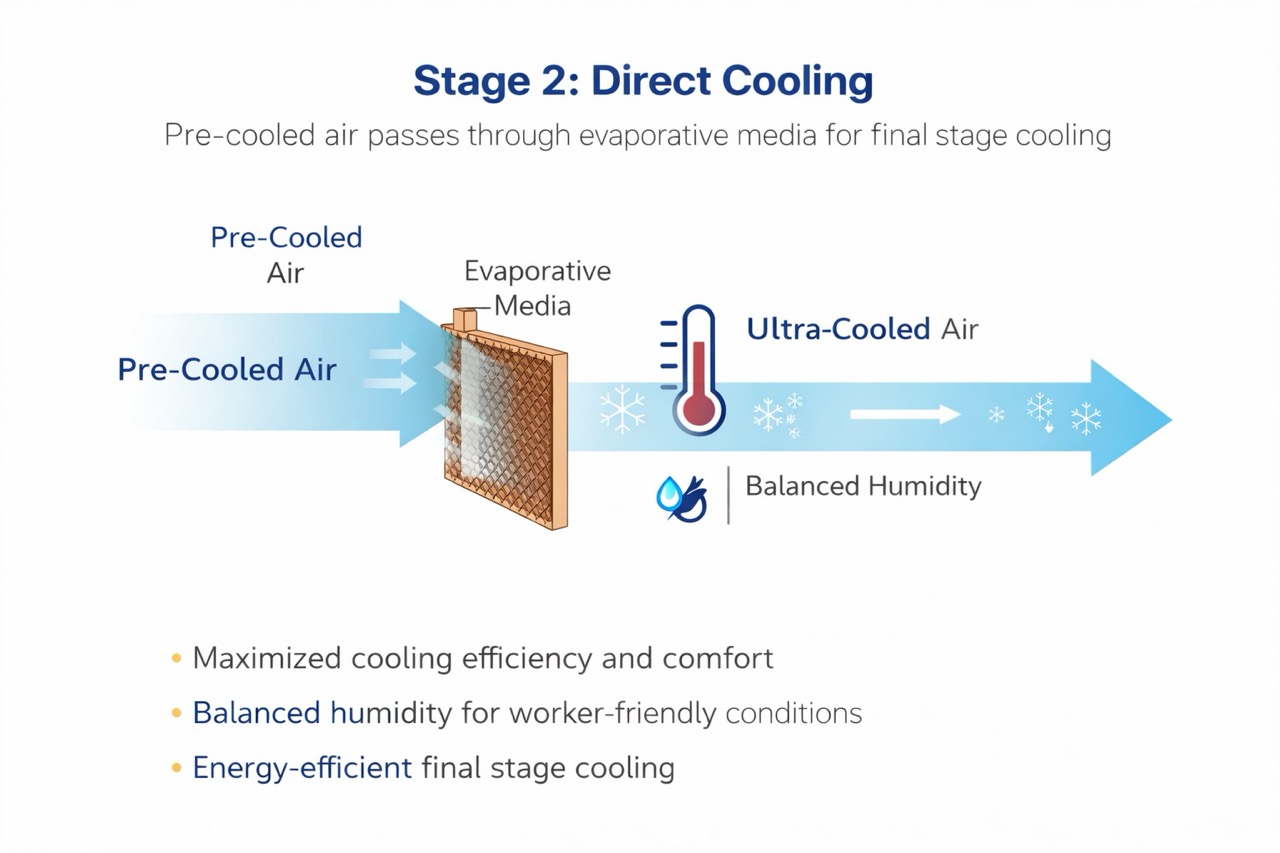

Stage 2: Direct Cooling

In the second stage, the pre-cooled air passes through evaporative media, where controlled evaporation provides additional cooling. Since the air is already pre-chilled, final temperature levels are significantly lower with minimal humidity impact.

- Maximized cooling efficiency and comfort

- Balanced humidity for worker-friendly conditions

- Energy-efficient final stage cooling

Importance of Two-Stage Cooling Systems

Energy Efficiency

Uses up to 60% less energy than traditional HVAC systems.

Enhanced Comfort

Provides cooler air with limited moisture, suitable for both people and processes.

Environmentally Friendly

Reduces carbon footprint by leveraging water-based cooling rather than refrigerants.

Operational Flexibility

Adapts easily to various temperature and humidity requirements.

Key Benefits

- Consistent and balanced temperature control

- Reduced operational costs and maintenance

- Lower humidity impact compared to single-stage systems

- Sustainable, eco-friendly performance

- Enhanced indoor air quality

Ideal Applications

Manufacturing Plants and Assembly Lines

Manufacturing Plants and Assembly Lines

Food & Beverage Production Units

Food & Beverage Production Units

Large Warehouses and Distribution Centers

Large Warehouses and Distribution Centers

High-Density Workspaces

High-Density Workspaces

Electronic and Pharmaceutical Facilities

Electronic and Pharmaceutical Facilities

Why Choose WCSIPL?

- Customized designs for every industrial layout

- Proven track record in large-scale climate solutions

- End-to-end implementation and maintenance support

Weather Controlling Solutions India Pvt. Ltd. (WCSIPL) delivers engineered Two-Stage Evaporative Cooling solutions designed for industrial and commercial environments requiring enhanced temperature control, higher comfort levels, and improved energy efficiency across Pune, Maharashtra, Gujarat, Chennai, Delhi NCR, Telangana, Hyderabad, Andhra Pradesh, and pan-India. With over 17 years of turnkey engineering experience, we design and execute indirect-direct evaporative cooling systems that combine sensible heat reduction through indirect cooling with high-volume direct cooling to achieve lower supply air temperatures without introducing excess moisture into the occupied space. Our two-stage evaporative cooling solutions are tailored to site-specific conditions such as heat load intensity, ventilation requirements, process sensitivity, and climatic variations, making them ideal for manufacturing plants, food processing facilities, warehouses, assembly halls, and utility areas. Seamlessly integrated with industrial ventilation strategies, ducting and air distribution layouts, electrical coordination, utility services, and fire-fighting systems, WCSIPL’s design-build approach emphasizes stable performance, reduced operating costs, and long-term reliability, enabling large facilities to achieve sustainable cooling, improved indoor air quality, and scalable infrastructure aligned with evolving operational demands.

- – Namkeen Production

Our specialists are ready to deliver customized, efficient, and reliable cooling solutions for your industrial needs.